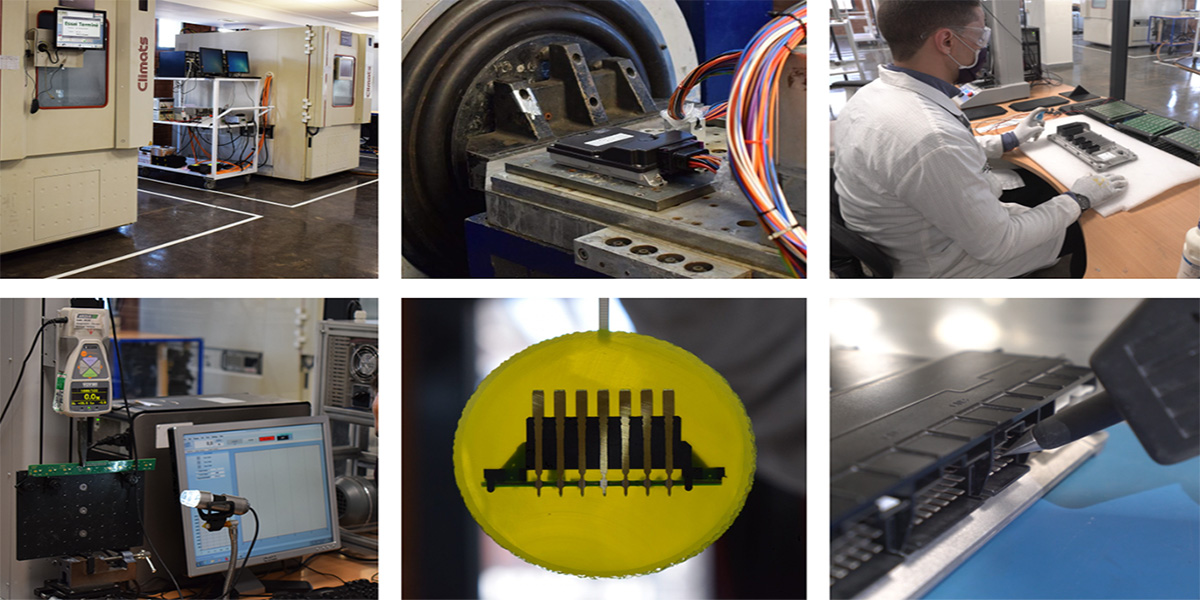

ACTIA Engineering Services, an R&D centre and North Africa’s first test laboratory to receive ISO 17025 certification in the field of thermomechanical testing, recently took a major step forward in terms of electronic testing & qualification with its acquisition of two items of high-tech equipment enabling it to maintain its position as a leading test laboratory. These two new additions, a high-tech vibration system for the thermomechanics activity and a latest-generation inverted optical microscope for the microsectioning activity, demonstrate the commitment by ACTIA Engineering Services to rise to the increasing challenges of qualifying electronic circuit boards & products. Let’s see how.

With revolutionary equipment contributing to ACTIA’s excellence in electronic qualification

From high-speed trains to large airliners, technological advances are significantly transforming on-board electronic products, pushing the boundaries of innovation, and creating new challenges in terms of electronic qualification. This qualification plays a vital role in ensuring the reliability and performance of on-board products. The challenges faced by electronic test laboratories are increasingly complex and demanding. This is why ACTIA Engineering Services has now acquired two new major pieces of equipment enhancing its capacity to address the challenges of electronic qualification in an ever-changing environment.

The electronics test laboratory acquires a vibration system with extended capacity

ACTIA Engineering Services’ new shaker opens up new opportunities in the field of thermomechanical analysis. The laboratory already had two vibration systems, and this new addition is a major development. Its 40kN vibration force and 80kN mechanical shock capabilities allow for even more precise simulation of the extreme environments to which the on-board products may be exposed.

Thanks to this cutting-edge technology, the laboratory is able to assess the resistance and durability of electronic components in response to heavy vibration. The on-board products must respond to demanding operating conditions, such as engine vibrations, shocks during transportation or movement in harsh environments. By accurately reproducing these constraints, the new vibration system allows the products to be tested and ensures their optimal performance under real conditions.

An inverted optical microscope for the electronics test laboratory: an in-depth view of the reliability of components and electronic circuit boards

The ACTIA Engineering Services laboratory has also acquired a latest-generation inverted optical microscope, offering a revolutionary breakthrough in the field of microsection analysis. This high-performance equipment allows for Macro & Micro structural examination of materials and electronic components with exceptional resolution and clarity.

With a measurement accuracy of 0.01µm, this inverted optical microscope offers a range of microsectioning services that are essential for electronic qualification. It can be used for characterising printed circuit boards, analysing solder joints, and carrying out optical microscopic examinations.

Electronics tes laboratory supports its customers in the reliability of technology products.

“In our organisation, we understand the importance of providing quality service that is quick and reliable, while complying with national and international standards and regulations in force across the world.”

explains Walid Rouis, CEO of ACTIA Engineering Services.

Stringent quality requirements

Electronic qualification plays a vital role in ensuring the reliability of technology products. In a world where technological developments are constantly redefining innovation standards, it is essential to ensure that on-board products meet the most stringent quality requirements.

Launching on the European market requires careful consideration of personal and environmental safety, by complying with directives and new regulatory approaches. The concept of free movement of goods is central to this goal, enabling qualified products to move freely across the borders of the European Union. In this context, the primary responsibility lies with the manufacturer or its representative, who must guarantee that its products meet the required safety and performance standards.

Cutting-edge solutions for electronic qualification

Simplified procedures, such as self-certification, have been implemented in order to facilitate this process. This allows manufacturers themselves to declare the compliance of their products with specific regulatory requirements. Nevertheless, it is essential that these self-certifications are made on the basis of stringent testing and authenticated methods in order to ensure an accurate and reliable assessment of the products.

“As an organisation specialised in electronic qualification, our role is to ensure that technology products meet the highest standards in terms of reliability and safety. We are committed to implementing advanced testing methods and processes to assess product performance, detect potential faults and guarantee uncompromising quality.

For example, we have implemented two new test protocols:

says Nizar Dhouib, microsectioning technical leader, at the ACTIA Engineering Services test laboratory.

– a protocol for checking counterfeit components, which is in high demand, following the electronic component supply crisis, during & after Covid,

– and a protocol for characterising resistance welds, used in particular in assembling battery cells for electric bikes,”

ACTIA’s commitments to compliance, quality and innovation enable it to provide cutting-edge solutions for electronic qualification, thereby helping to create a European market of safe and reliable equipment for everyone.

By performing a diverse range of tests, meeting the requirements of various electronic product sectors

The ACTIA Engineering Services test laboratory is constantly committed to supporting its customers in conducting the qualification tests required by the applicable normative references, in order to guarantee the optimal reliability of their products.

The tests performed cover various key areas to ensure the reliability and durability of the products.

Mechanical and combined tests

These tests make it possible to simulate the physical constraints to which the products may be subjected. They assess resistance to shocks, vibrations, and falls, as well as the general robustness of the product under real operating conditions.

Climatic and thermal tests

The aim of these tests is to assess the products’ capacity to operate in extreme conditions. They include temperature cycling, testing resistance to moisture, heat and cold, as well as simulations of specific atmospheric conditions. These serve to check the performance and stability of the products under various conditions.

The laboratory also performs corrosion and chemical tests

This is to assess the products’ resistance to aggressive environmental conditions. These tests reproduce corrosive conditions, chemical exposures, and potential interactions with corrosive or aggressive substances, in order to guarantee the durability and integrity of products.

PCB (Printed Circuit Board) and PCBA (Printed Circuit Board Assembly) tests

These tests are specifically for assessing printed circuit boards. They serve to check the quality of electrical connections, compliance of components, overvoltage resistance, as well as the overall performance of printed circuits under real conditions of use.

Microsection tests

These provide an in-depth analysis of the internal structure of electronic components. Using advanced microscopes, they help to detect weld faults, cracks, inclusions, or any other problem that may compromise the reliability of the products.

Electromagnetic compatibility (EMC) tests

These are performed to assess the products’ capacity to properly function in the presence of electromagnetic interference. These tests check compliance with EMC standards and ensure that the products are protected against electromagnetic disturbances which may impair their operation.

The design of simulation brackets for dedicated tests: an additional service for electronics test laboratory

The mounting brackets developed by the AES laboratory ensure the stability and safety of the electronic equipment, wiring and mechanical components during the tests.

Custom brackets

The custom simulation test brackets are designed with consideration given to the precise specifications of each product to be tested. They guarantee resonance-free attachment, thereby minimising any interference and ensuring reliable and replicable test conditions. Due to their effective design, these brackets allow vibration, shock, and mechanical stress tests to be performed while maintaining product integrity.

The design of test brackets represents added value for the laboratory

By developing these dedicated simulation test brackets, ACTIA Engineering Services provides added value in terms of guaranteeing costs and lead times for tests.

This helps to:

- Reduce qualification lead times,

- Optimise costs associated with the tests

- Ensure greater reliability of the results obtained.

In conclusion, the acquisition of these two new major items of equipment strengthens ACTIA Engineering Services’ position as a leading player in the field of electronic qualification. Due to its understanding of standardised test methods, its high-performance equipment and its accredited resources, the laboratory offers a wide range of tests and cutting-edge expertise for on-board products.

Supported by an extensive network of private and state partner laboratories, ACTIA Engineering Services rounds out its service offering and enhances its capacity to meet the specific needs of international customers.