Advanced Driver-Assistance Systems (ADAS) are vehicle features that provide both safety and comfort to the driving experience. They are increasingly used to equip vehicles, to such an extent that in 2024, all new vehicles will be equipped with these ADAS devices. People working in the repair sector: panel beaters, windscreen replacement experts and professionals working on multiple activities must study this change to vehicles, which is revolutionising their profession. Operations that require driving-assistance system calibration now take place daily.

The ACTIA ADAS solution supports professionals with a solution that is extremely easy to use and very accurate. ACTIA equipment enables rapid work and extreme precision, in line with manufacturer procedures. Discover how ACTIA ADAS solutions turn repair professionals into calibration specialists.

ADAS IS REVOLUTIONISING THE CAR REPAIR PROFESSION

What are ADAS systems?

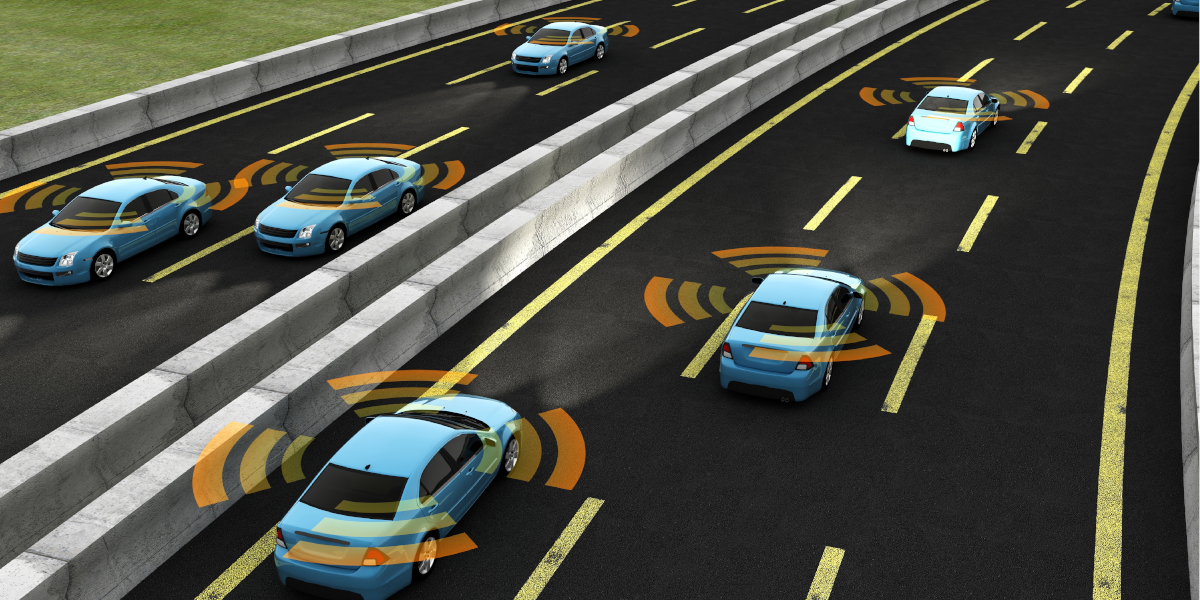

ADAS systems are based on environmental perception thanks to cameras, radars, LiDAR (laser remote sensing) and ultrasound. This equipment detects critical situations and warns the driver of any imminent hazards.

ADAS includes all driver information or assistance systems such as:

- 360° vision,

- Adaptive Cruise Control,

- Emergency braking,

- Blind spot detection

- Lane keeping assist,

- Parking assist,

- Smart headlights,

- Traffic sign recognition.

Regulatory aspect: Seven items of equipment that will soon be mandatory

To decrease the number of road accidents mainly caused by human error, the European Commission adopted a new measure on 16 April 2019 to improve the safety of new vehicles marketed within the EU. Therefore, by 2022-2024, all new vehicles must include seven essential ADAS devices:

- Intelligent Speed Assistance (ISA),

- Alcohol interlock installation facilitation,

- Driver drowsiness and attention warning system,

- Advanced driver distraction warning system,

- Emergency stop signal,

- Reversing detection.

In addition to these instruments, there is an event data recorder, i.e., a black box, that records the driving data in the seconds leading up to an accident.

ADAS is revolutionising a whole profession

These systems function partly thanks to cameras, notably installed on the windscreen. These cameras wholly depend on precise installation and calibration to accurately detect the environment outside your car. Auto repair shops will need to work on these systems more and more frequently. The complexity affects all repair professionals: auto repair shop professionals, panel beaters, window specialists, etc.

Driving assistance uses new technologies and therefore calls for new repair methods. As a result, new skills are emerging in auto repair shops. In addition, operations are longer and more technical. This new know-how is accessible to all repair professionals, provided of course that they are supported and have an excellent calibration tool. ACTIA equipment helps professionals in this skill improvement.

ADAS must be calibrated further to the following operations:

- Windscreen replacement,

- Work and adjustments on the suspension and/or running gear,

- Bodywork,

- Replacement of ECUs or sensors.

ADAS AND GEOMETRY, THE PERFECT PARTNERSHIP FOR ACCURATE, SAFE CALIBRATION

The thrust angle is at the heart of ADAS calibration.

ADAS calibration guarantees the alignment of cameras or radars with this line of travel. A moving vehicle follows a line of travel depending on its geometry. This alignment of the running gear geometry can be supplemented by ADAS system calibration based on the manufacturer thrust angle. The thrust angle is the angle formed by the thrust axis and the axis of symmetry. It determines the axis of trajectory for the rear wheels. These are the reference for the alignment of the vehicle’s front and rear axles. The detector and its target will therefore be perfectly aligned with the trajectory axis of the rear wheels. This is what guarantees the reliability of the measurements. These measurements must be located within the tolerance range communicated by the vehicle manufacturer.

Two ways to calibrate ADAS systems

There are two calibration procedures that may vary from one vehicle to another. They depend on the brand, the model or the year of the vehicle. The vehicle may require static or dynamic calibration.

Static calibration involves placing a target in the centre of the vehicle at the distance and height recommended by the manufacturer, perpendicular to the thrust angle. The brands that require an ADAS detector are as follows: Alfa Romeo, Audi, Fiat, Hyundai, Kia, Mazda, Mercedes-Benz, Nissan, Renault, Seat, Skoda, Smart, Toyota, Volkswagen, etc.

Dynamic calibration, i.e., whilst driving, consists in calibrating the camera and radar using a diagnostics tool during a road test. Learning therefore does not require an ADAS detector.

How can ADAS be calibrated in 15 min. only (static method)?

1-Check the vehicle thrust angle: by attaching the measurement heads to the wheels, the repair professional checks that the thrust angle values are within the manufacturer’s tolerances.

2-Position the vehicle and the ADAS detector: the repair professional will use the measurement heads for optimal positioning.

3-Calibrate the ADAS with the Multi-Diag 360 software: put the vehicle in communication with Multi-Diag by connecting the communication interface. The Multi-Diag “Profession Function” enables repair professionals to electronically and very easily calibrate the ADAS.

ACTIA ADAS CALIBRATION EQUIPMENT

The equipment is composed of four light Bluetooth measurement heads with 24-hour autonomy, as well as a 100% ACTIA software: Wheel-Diag ADAS, including a database. As an option, a tablet offers repair professionals the mobility required in the auto repair shop for these calibration operations.

Wheel-Diag software – clear and didactic

Wheel-Diag may be installed on a tablet, on a desktop or laptop, or on a geometry console. It includes the geometry adjustment and control program as well as the guided positioning procedures for the detector and the targets. Learning how to use the tool is guided, from vehicle preparation to confirmation of ADAS calibration.

As an option, Multi-Diag 360 supplements the ADAS solution for the ACTIA multibrand diagnostics software, which covers 50 brands, 5,000 vehicle models and over 100,000 systems.

Modular geometry device

Wheel-Diag ADAS is the first mobile geometry tool. Because it is modular, it can be adapted to any diagnostics tool on the market. The compatibility of this new geometry test bench with ADAS systems makes it a modular solution, offering the technician repair that is fully compliant with manufacturer standards.

The whole mobile solution, on swivel wheels, is composed of a target support with height and perpendicularity adjustment thanks to easy-to-access control wheels.

Detector on wheels with VAG targets included

The mobile detector enables quick positioning. It also makes it easier to change the targets. Calibration is accurate thanks to the sensitivity of the measurement heads. The target kit is scalable over time.

ADAS calibration is a real challenge for the repair profession, but is also an opportunity for advancement. ACTIA supports repair professionals by offering effective, reliable and easy-to-use tools.

Vehicles with ADAS systems are classified as level 2 in the autonomy hierarchy – we have already discussed this classification of smart and autonomous vehicles. By integrating ADAS in our multi-brand offering, ACTIA is enhancing our market positioning for connected vehicles, which are becoming increasingly smart. ACTIA is therefore preparing for the smart automated mobility of the future.

Visit Diag & Repair website Contact our diagnostics experts